The steel industry is an essential component of the global economy, contributing to various sectors including construction, automotive, and manufacturing. As we approach 2024, technological advancements are significantly influencing Steel Exporters, shaping the way they operate and compete in the international market. This blog explores the various impacts of these technological changes, focusing on how they enhance productivity, improve product quality, and open new market opportunities.

Understanding the Steel Industry in 2024

The Role of Steel in Modern Industries

Steel remains a cornerstone material used across various industries due to its strength, durability, and versatility. It plays a critical role in building infrastructure like bridges, buildings, and railways, as well as in manufacturing cars, ships, and appliances.

The Global Steel Market Overview

As of 2024, the global steel market continues to grow, driven by increasing urbanization and industrialization, especially in emerging economies. Steel exporters are crucial players, meeting the demand across continents and ensuring a steady supply of this indispensable material.

Technological Trends Shaping Steel Exporters

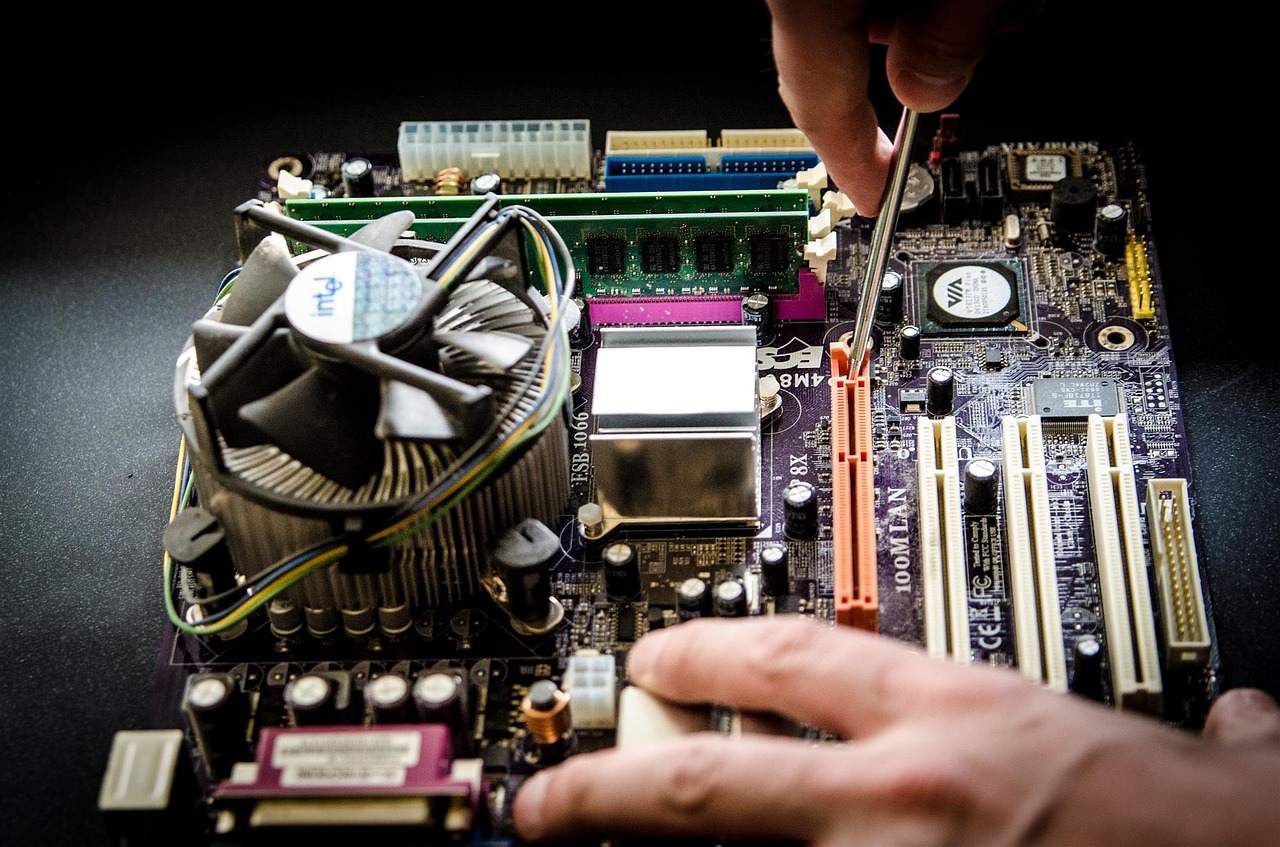

Automation in Steel Production

Automation technology has transformed steel manufacturing, making processes more efficient and less labor-intensive. Automated machinery and robotics are now common in steel plants, performing tasks ranging from raw material handling to the assembly of finished products.

Benefits of Automation:

- Increased Production Speed: Machines work faster than humans, which speeds up production.

- Consistency and Quality: Automated processes reduce human error, enhancing the quality of steel.

- Reduced Costs: Automation lowers the labor costs and reduces waste, optimizing overall expenses.

Advanced Materials and Techniques

In 2024, the introduction of advanced materials and innovative manufacturing techniques continues to evolve, allowing exporters to produce higher-quality steel with enhanced properties such as increased strength, flexibility, and corrosion resistance.

Examples of Technological Innovations:

- High-Strength Steel Alloys: These are crucial for applications requiring durable yet lightweight materials, such as in the automotive industry.

- Coating Technologies: Advanced coatings that prevent rust and corrosion extend the life of steel products.

Green Technology in Steel Manufacturing

Environmental concerns have led to the adoption of green technologies in steel production. These technologies aim to reduce the carbon footprint of steel manufacturing and make the process more sustainable.

Key Green Technologies:

- Electric Arc Furnaces (EAF): These use electrical energy to melt recycled steel, significantly reducing carbon emissions compared to traditional methods.

- Carbon Capture and Storage (CCS): This technology captures carbon dioxide emissions from steel plants and stores them underground to prevent atmospheric release.

Impact of Technological Advancements on Steel Exporters

Enhanced Global Competitiveness

Technological advancements have equipped steel exporters with tools to enhance their efficiency and product quality, making them more competitive on a global scale. Exporters who adopt these technologies quickly can better meet the demands of international clients, adhering to stringent quality and environmental standards.

Challenges and Opportunities

While technology offers numerous advantages, it also presents challenges. The initial cost of integrating advanced technologies can be high, and there is a continuous need for employee training and development to keep pace with technological changes.

Opportunities for Growth:

- Market Expansion: Advanced technologies enable exporters to produce specialized products, opening up new market segments.

- Innovation Leadership: By leading in technological adoption, steel exporters can establish themselves as market leaders in innovation.

Case Studies of Successful Implementations

Illustrative examples of steel exporters who have successfully integrated new technologies could highlight how these changes have led to improved efficiency and market expansion. These real-life scenarios provide practical insights into the benefits and challenges faced during technology adoption.

The Future Outlook for Steel Exporters in 2024

Looking ahead, the steel industry is poised for further transformations as technological advancements continue to emerge. The focus is likely to remain on sustainability, with increased pressure to adopt eco-friendly practices and technologies.

Predictions for Technological Developments:

- Smart Manufacturing: The use of AI and IoT in manufacturing processes is expected to grow, providing real-time data to optimize operations.

- Increased Recycling Efforts: Technologies enhancing the efficiency of steel recycling will play a crucial role in promoting sustainability.

Conclusion

The impact of technological advancements on steel exporters in 2024 is profound and multifaceted. By embracing these changes, exporters can improve their operational efficiency, product quality, and environmental sustainability, thus securing a competitive edge in the global market. As technology continues to evolve, staying ahead of these trends will be essential for any steel exporter aiming to succeed in this dynamic industry.

For more stories and info like this, www.webbacklink.com.au/ is the place to be.