Welcome to our comprehensive guide on pneumatic rubber fender, an essential component in marine and offshore industries. In this article, we’ll delve into the practical applications, benefits, and key considerations of these versatile fenders, designed to protect vessels and structures during berthing and mooring operations.

Understanding Pneumatic Rubber Fenders

What are Pneumatic Rubber Fenders?

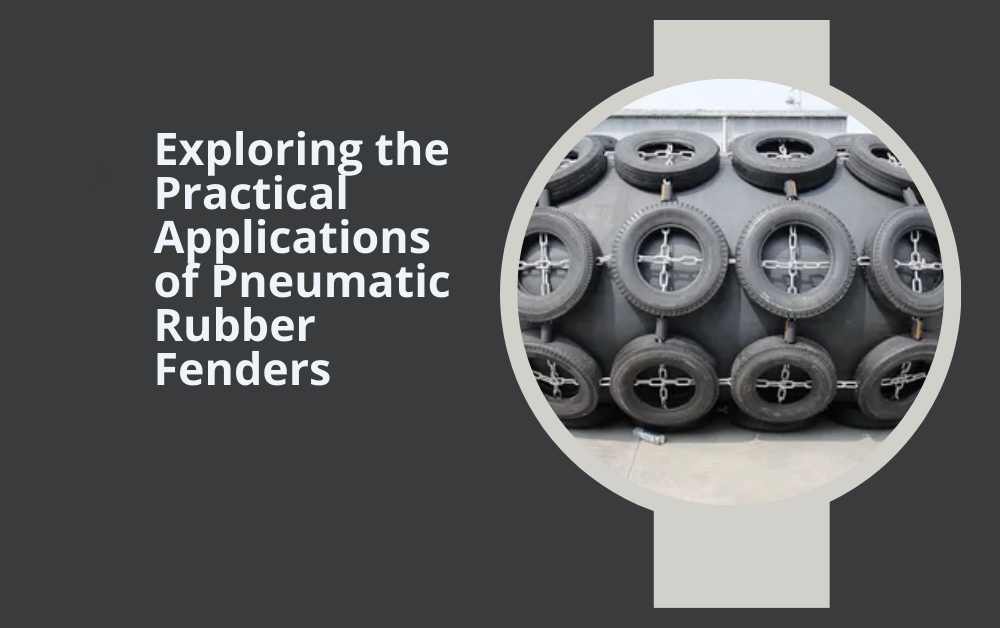

Pneumatic rubber fenders, also known as air-filled fenders, are cylindrical or spherical devices made of rubber and reinforced with layers of synthetic tire-cord. These fenders are filled with compressed air, providing excellent energy absorption and cushioning properties.

How Do Pneumatic Rubber Fenders Work? When a vessel approaches a berth or structure, pneumatic rubber fenders absorb kinetic energy by compressing the air inside, thus reducing impact forces and preventing damage to both the vessel and the berthing structure. The elastic nature of rubber allows these fenders to return to their original shape after compression, ensuring long-lasting performance.

Practical Applications of Pneumatic Rubber Fenders

1. Ship-to-Ship (STS) Transfer Operations Pneumatic rubber fenders play a crucial role in ship-to-ship transfer operations, providing a safe and reliable means of transferring cargo and personnel between vessels. These fenders absorb the impact between ships during the transfer process, minimizing the risk of collisions and damage to hulls.

2. Berthing and Mooring Operations In berthing and mooring operations, pneumatic rubber fenders act as a protective barrier between the vessel and the quay or jetty. By absorbing energy and reducing impact forces, these fenders prevent structural damage to both the vessel and the berthing facility, ensuring smooth and efficient operations in ports and harbors.

3. Offshore Platforms and Floating Structures Pneumatic rubber fenders are also used to protect offshore platforms, floating docks, and other marine structures from the impact of vessels and adverse weather conditions. By absorbing energy and dissipating forces, these fenders help maintain the integrity and stability of offshore installations, reducing maintenance costs and downtime.

Benefits of Pneumatic Rubber Fenders

1. Superior Energy Absorption One of the key benefits of pneumatic rubber fenders is their ability to absorb large amounts of energy during impact, reducing the risk of damage to vessels and structures. This makes them ideal for high-traffic areas such as ports, where vessels of varying sizes and tonnages require reliable protection.

2. Low Maintenance Requirements Pneumatic rubber fenders are relatively low maintenance compared to other types of fenders, thanks to their durable rubber construction and simple design. Routine inspections and occasional cleaning are typically all that’s required to ensure optimal performance and longevity.

3. Versatility and Customization These fenders are available in a wide range of sizes and configurations to suit different vessel types and berthing conditions. Whether it’s a small fishing boat or a large oil tanker, pneumatic rubber fenders can be customized to provide the right level of protection for any application.

Key Considerations When Choosing Pneumatic Rubber Fenders

1. Operating Conditions Consider the operating conditions, including water depth, tidal range, and environmental factors such as waves and currents, when selecting pneumatic rubber fenders for a particular application. Fenders must be capable of withstanding the forces exerted during berthing and mooring in challenging marine environments.

2. Vessel Size and Type The size and type of vessels frequenting the port or berthing facility will influence the selection of pneumatic rubber fenders. Larger vessels require fenders with higher energy absorption capacity, while smaller vessels may require smaller, more maneuverable fenders.

3. Installation and Maintenance Ensure proper installation and regular maintenance of pneumatic rubber fenders to maximize their effectiveness and lifespan. This includes inspection for signs of wear and damage, as well as adherence to manufacturer recommendations for inflation pressure and maintenance intervals.

Conclusion:

Pneumatic rubber fenders are indispensable components in maritime and offshore industries, providing essential protection for vessels, ports, and marine structures. With their superior energy absorption, low maintenance requirements, and versatility, these fenders offer a reliable solution for mitigating the risks associated with berthing and mooring operations. By understanding their practical applications and key considerations, stakeholders can make informed decisions when selecting and deploying pneumatic rubber fenders for their specific requirements.

Note :- For more insightful articles related to this topic, feel free to visit www.webbacklink.com.au.